Shijiazhuang Bell Precision Electronic Technology Co., Ltd. is a professional enterprise engaged in high-precision chemical etching parts.

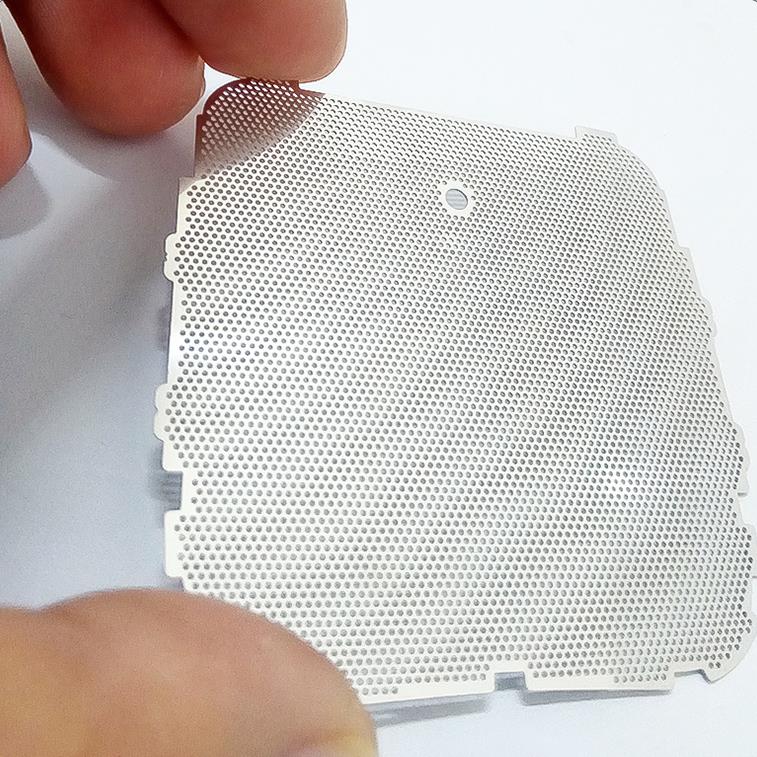

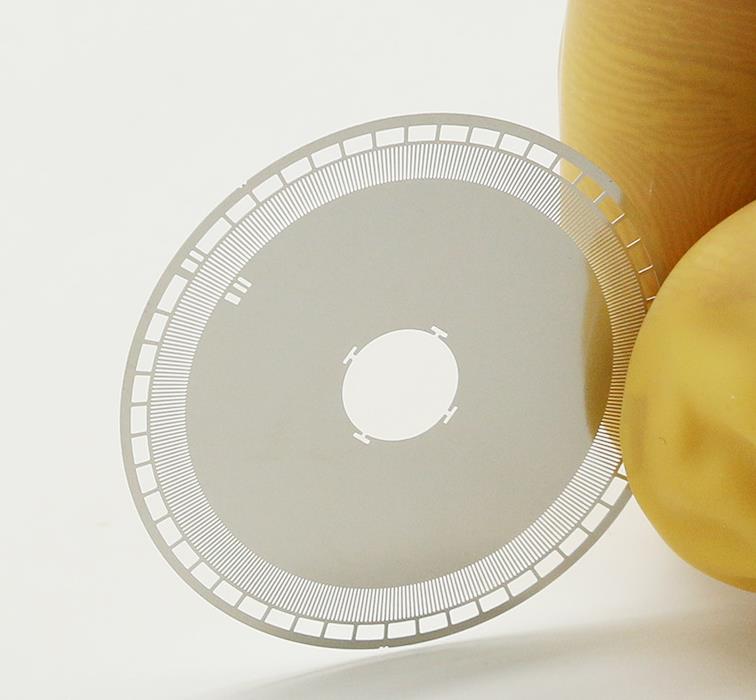

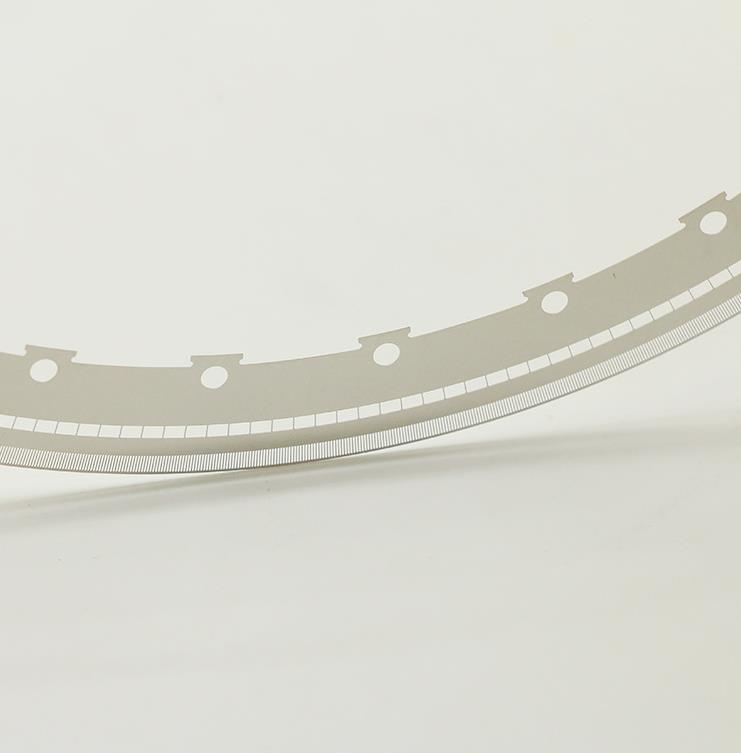

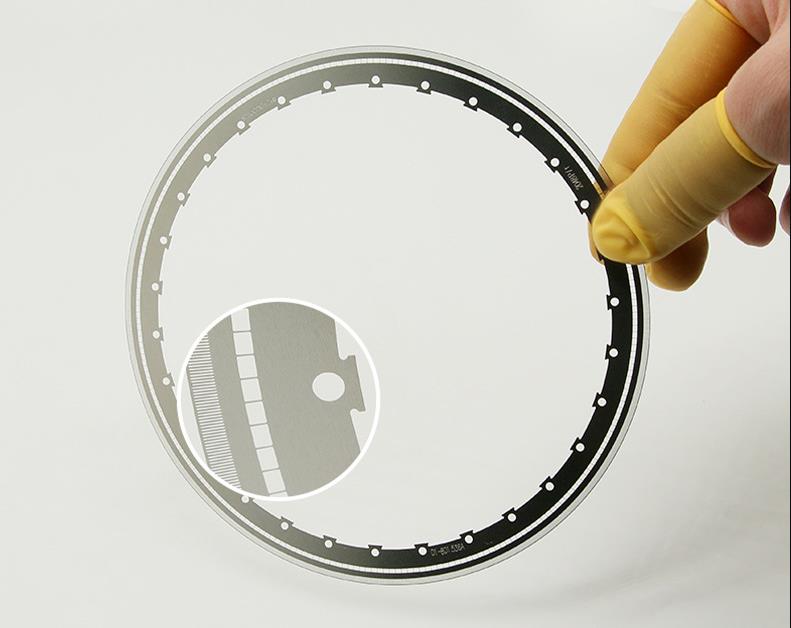

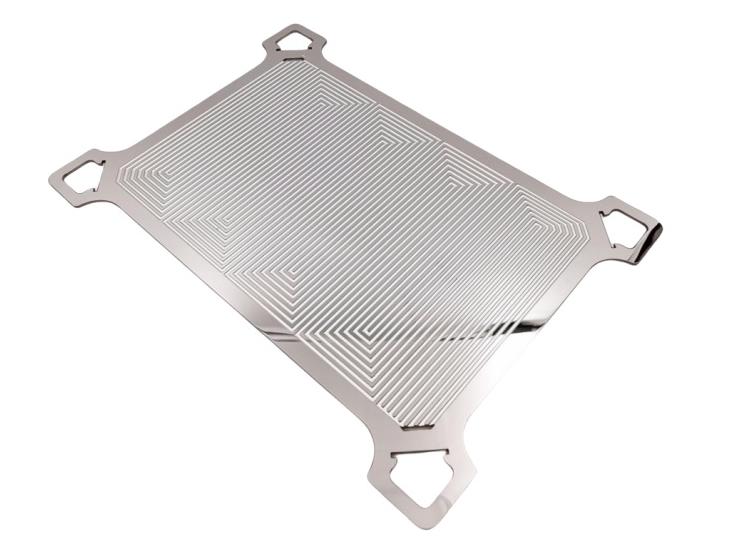

- High-end metal processing and manufacturing (resistance pieces, valve pieces, apertures, filters, processing and manufacturing of metal atomization sheets, etc.);

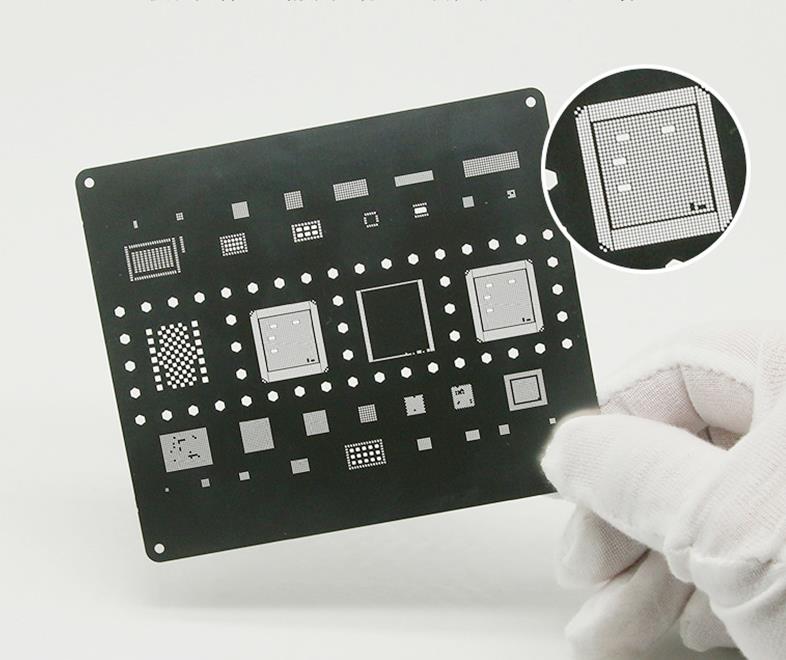

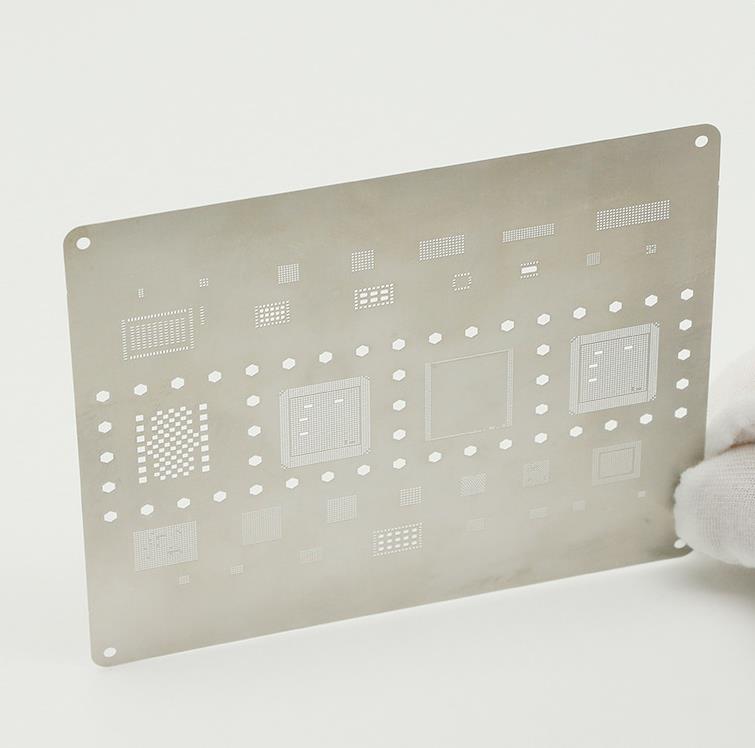

- stainless steel manufacturing and processing, metal MASK, metal processing and manufacturing, etc.;

- Precision parts manufacturing and processing .

PRODUCTS

We offers chemical etching componets of ferronickel,stainless steel,copper and other material. Our products are mainly used in integrated circuits, aerospace, petrochemical, electronic communications, new energy vehicles and other fields.

Precision

Exceptional Precision and Accuracy . Accuracy to ±0.1~0.03mm.

Fast Prototyping

Prototype to high volume production.Custom features at no additional cost.

Smooth Surface

100% burr and stress free precision components by chemical techniques.

AOI Inspection

Automated Optical Inspection, more efficient and accurate.

Let's see how it work.

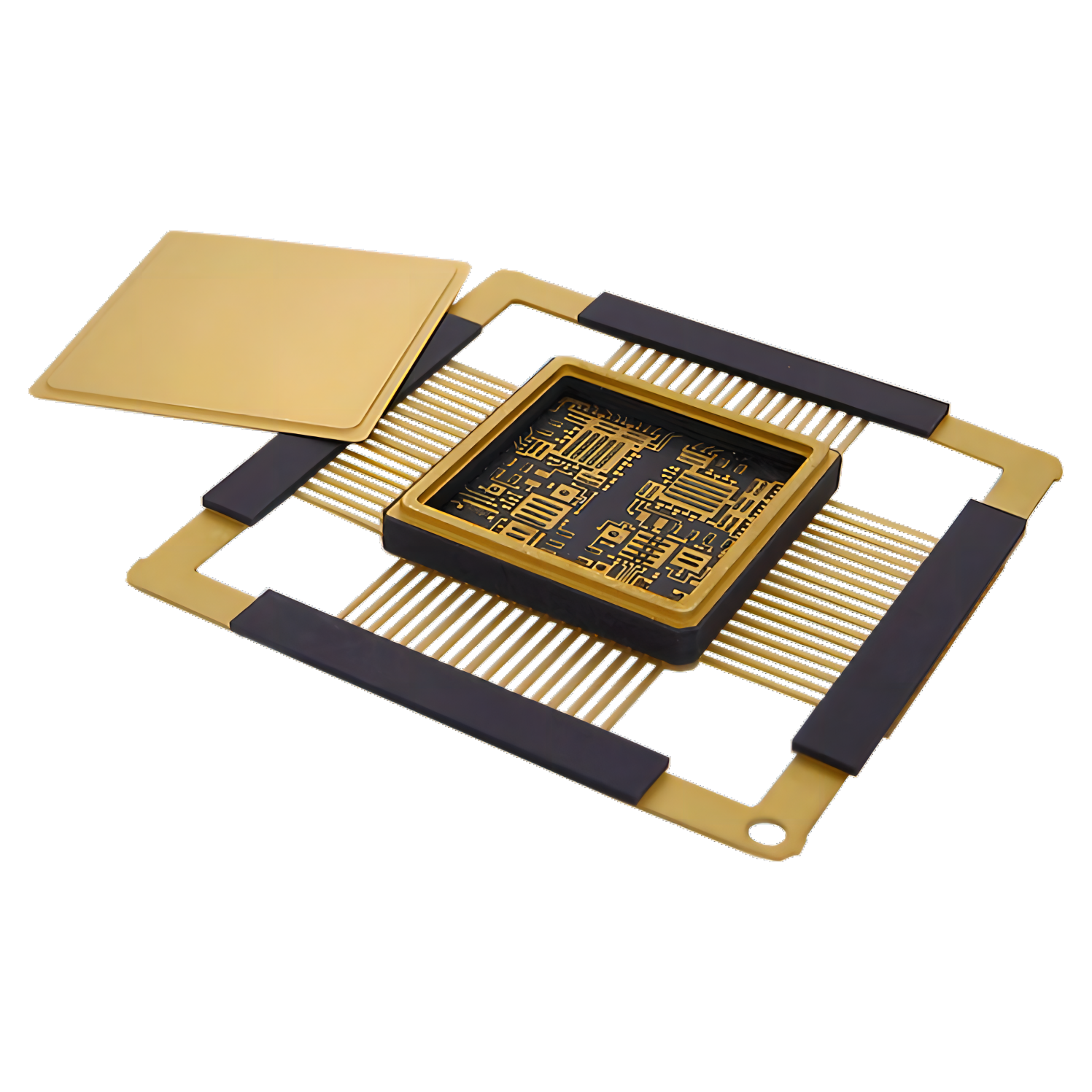

The chemical photoetching process begins with the application of a photosensitive film, called photoresist, onto a metal or thin film substrate. This film is then exposed to a pattern of light through a mask, causing the exposed areas to either harden or become soluble depending on the type of photoresist used. After developing, the resist protects the desired areas while the uncovered metal is chemically dissolved in an etchant bath. Once the etching is complete, the remaining photoresist is removed, revealing the precisely etched pattern on the substrate.

Industries Served

Chemical etching finds extensive application across various industries due to its ability to create precise and complex patterns on a substrate.

Energy

Automotive

Enough Talk, Let’s start a project together !

The company not only has a variety of advanced equipment and instruments, but also has a group of professional and technical personnel, the company specializes in the research and application of photochemical etching technology, we take high quality, low cost, good service as the competitiveness of the enterprise, forming a unique living space of the enterprise.

CALL US NOW !